About RoboShop's Vibratory Systems

A modern alternative to conventional material conveying methods

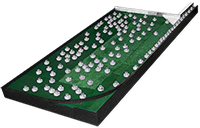

Our Vibratory Conveyors are beltless vibratory feeders, capable of moving parts ranging from very small, light components to steel bars weighing over 300 pounds. Our conveyors are compact, low-maintenance, durable, and infinitely adaptable so as to suit any application. Vibratory feeders provide an excellent alternative to clunky, single-purpose belted conveyors, allowing for gentle part handling, multidirectional conveyor movement, organization, and accumulation, all on a single feeder bed.

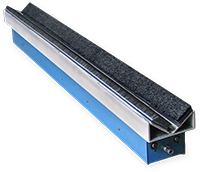

Vibratory conveyors consist of a reciprocating surface plate covered with a durable directional biased brush surface that uses friction and angled fibers to feed materials in the direction of the brush. By reducing the number of moving parts, we are able to make our feeders more compact, more dependable, and more versatile than an ordinary conveyor belt system. You will be amazed at the applications our Vibratory Conveyors can satisfy!

For more information on the specifics of our vibratory feeders, click the “How it Works” link.

To see picture and video examples of our three types of vibratory feeder systems, peruse our products list to the right.

Features

- A direct replacement for belt conveyors

- Vibratory -- no belts and no pulleys

- Low maintenance -- minimal moving parts

- Durable -- industrial nylon brush surface

- Electro-magnetic drive -- very durable, dirt and moisture resistant

- Low profile -- no motor -- standard unit 4.5" high and 4" wide

- Feed-rates up to 60 feet per minute (part dependant)

- Full speed control with solid state drive

- Low power consumption -- less than 100 watts for a 12" W x 72" L section

- Can be placed end to end with 1/8" gap for long conveying needs

- Can be placed at 90° to previous units to turn corners

- Special sections available for 30°-45°-60°-90° exits or entry

- 100% safe -- no guards required, no pinch points

- Can be inclined up to 20° to convey parts uphill

View or Download Product Brochure